At zadhooshcrane’s editorial team, we strive to share the expertise of our specialists in overhead crane manufacturing and engineering, accumulated over more than 40 years. Throughout our journey, we’ve encountered a diverse range of manufacturers using overhead cranes, from experienced professionals to newcomers. Our goal is to provide comprehensive knowledge about overhead cranes, starting from the basics and delving into more intricate details. Should you require further information on any section of the article, feel free to explore the related content or reach out to us through our contact page.

What Are Overhead Cranes?

Let’s begin with a fundamental question: What exactly is an overhead crane? In simple terms, it’s a machine designed to lift and move heavy loads from one location to another with precision. You’ve likely seen them in action—they’re ubiquitous, making our lives easier and workplaces more efficient.

In addition to their apparent efficiency, overhead cranes pursue two primary objectives: efficiency and safety. They can operate up to three times more efficiently than manual labor or traditional equipment, significantly enhancing productivity. Moreover, they are essential for ensuring worker safety, especially in hazardous environments where manual lifting poses risks.

Key Components of Overhead Cranes

1. Hook: This is where your load attaches to the crane for lifting and movement.

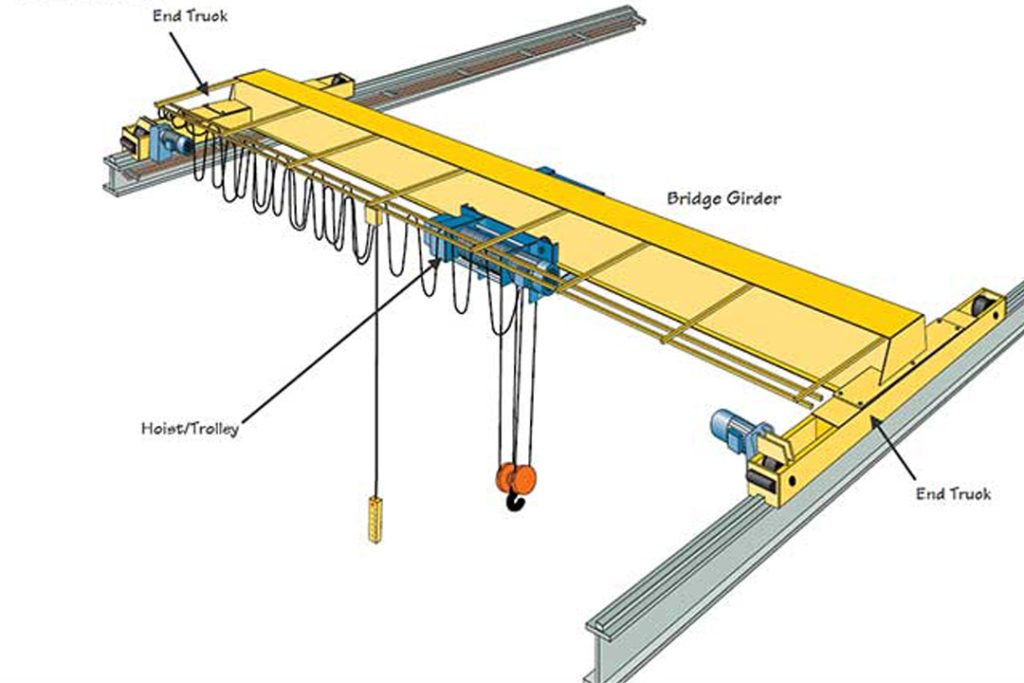

2. Hoist: Responsible for moving the hook up and down, mounted on the bottom of the bridge.

3. Trolley: Moves the hoist from side to side across the bridge.

4. Bridge: The load-bearing beam on which the trolley travels, available in top-running or under-running configurations.

5. Runway Beams: Allow the bridge to travel from one end to the other.

6. End Trucks: Physically drive the bridge along the runway, akin to the wheels and motors of a car.

7. Control Panel: Mounted on the bridge crane, it sends signals to the end trucks, facilitating movement through push buttons or radio controllers held by the operator.

Moreover, overhead cranes are powered by electrical systems, which bring power from the building to the crane and control the hoist’s movements.

Types of Overhead Cranes:

Overhead cranes come in various shapes, sizes, and capacities, each tailored to specific needs. Here are some common types:

1. Bridge Cranes:

This type of crane consists of two overhead runways and a bridge that moves along them. Typically equipped with a hoist and a trolley that travels along the length of the bridge, they can have single or double girders. Bridge cranes are used for heavy and large loads and are usually found in industrial environments.

Gantry Cranes:

In this type, the crane’s legs move on the ground or on installed rails. They are usually used in open spaces or environments with low ceiling height. Gantry cranes are suitable for heavy loads in industrial or airport settings.

Monorail Cranes:

In this type of crane, a single rail is installed on the ceiling or columns, and a trolley moves along it. These cranes are used for transporting loads in fixed and precise paths, usually in production lines or material transfer.

Jib Cranes: These cranes are mounted on walls or floors and are used for movement within a specific workspace angle or circle. They are typically used in environments with limited space for overhead cranes and are suitable for light to medium loads

Workstation Cranes: These cranes are designed for individual users and are used for tasks in a specific workstation. They are usually used in workshop environments or workshops with limited space and are suitable for light to medium loads

Conclusion

We hope this instructional article has provided you with valuable insights into the functionality and applications of overhead cranes. It’s essential to understand that each type of crane offers unique features and applications, allowing you to choose based on your requirements. Furthermore, zadhooshcrane, with its expertise in manufacturing and implementing various types of overhead cranes, is here to assist you in selecting the right crane for your specific needs.

At zadhooshcran, we are committed to providing top-notch material handling solutions while adhering to industry standards. If you’re interested in improving efficiency or safety in your workplace, our team is here to help at every stage.

We appreciate your support, and we value your partnership. As a token of our gratitude, we offer you a free online consultation session with our experts to help you choose the best type of crane. Simply contact our consultants via WhatsApp to schedule your consultation appointment.